| •Comprehensive upgrade utilizing State-of-the-Art Computer data processing technologies. |

| •Enhances the life of gear tester. |

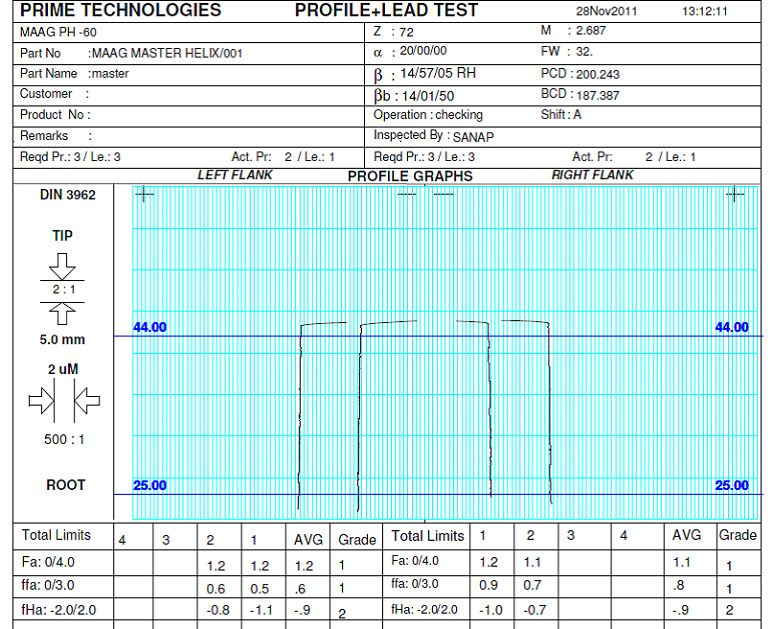

| • Fast and accurate evaluation of parameters accounting DIN 3960. |

| • Very low cost. |

| • No problem of service and spares. |

| • Modification of Adaption of software according to specific customer’s requirements. |

| • No special and expensive graph recording is required. |

| |

| Features: |

| • Evaluation of Profile and lead for Total Form error, Form error, Angle error and crowning. |

| • Error: Hollow crowning error, Tip relief, Root relief, Top end relief and bottom end relief. |

| • Quality of standard are free selectable as per DIN 3962, Din 1829 and JIS, AGMKA and user selectable. |

| • Provision to add machine specific data & corresponding calculation. |

| • Complete gear data management with gear code no., Drawing no. etc. |

| • Storing and recalling of gear profile/ results according to gear code no., Batch no, Customer’s code3 no., Data etc. |

| • Calibration software for LVDT probes and encoders with slip gauges. |

| • Special software module as per Volvo standards, BHEL requirements. |

| • Shaping and shaving cutters, DOP etc. |

| |

|

| |

| Gear Mas™ II |

| PC Retrofit for gear Pitch and Concentricity Tester |

| |

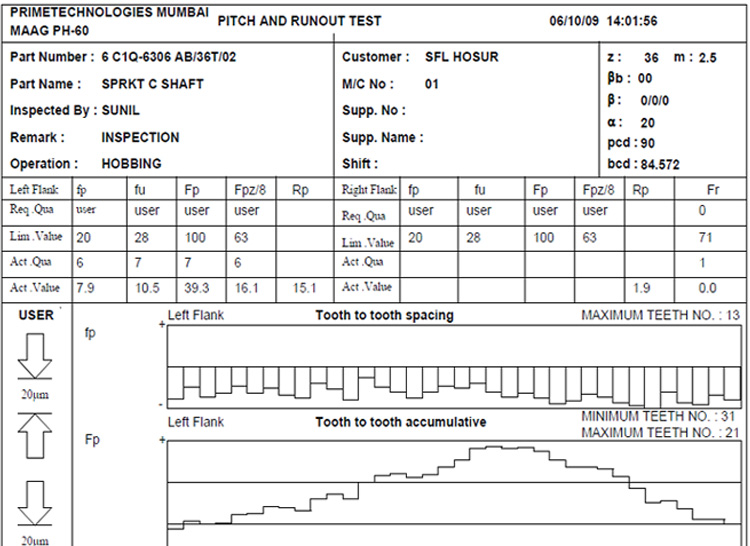

| GEAR MAS™ II is a State-of-the-Art Computerised system for pitch and concentricity Measurement. |

| |

| FEATURES: |

| |

| • User friendly Menu driven operation. |

| • Automatic evaluation of following parameters confirming to DIN 3960, DIN 3962, JIS Standards, DIN 1829, AGMA. |

| • |

fp-pitch Deviation. |

| • |

Fp-Cumulative pitch error. |

| • |

Fu-Adjacent Pitch error. |

| • |

Fr-Runout error. |

|

| • Automatic detection of DIN grade of measured job. |

| • Facility for user configurable tolerances. |

| • Provision for Archive/Recall of both standard and History data. |

| • Recalling of History as per part no. and date. |

| • Powerful reporting facility. |

| • Software calibration. |

| • Built-in hardware diagnosis program. |

| • Open ended design allows easy scope for adding many more user desired features. |

| |

| SYSTEM ELEMENTS: |

| • LVDT Type probe for pitch and Runout Measurement. |

| • Signal Conditioning Electronics. |

| • Filter Electronics |

| • ADC Eectronics. |

| |

|

| |

| |

| Gear Mas™ III |

| PC Retrofit for Gear Roll Tester |

| |

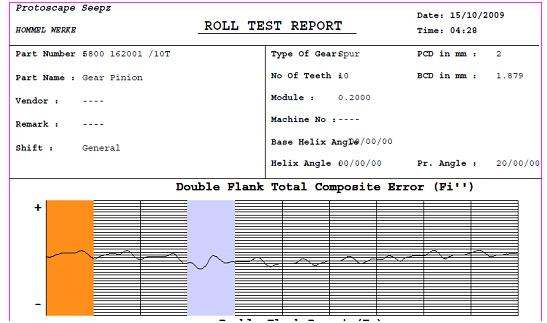

| PC Retrofit Gear Mas™ III is a State-of-the-Art PC based measurement and Analysis System for Gear Roll Tester. Gear Mas™ III can be used with double flank gear roll tester of any make like Carl Mahr, Goulder Mikron, Osaka or any Indian make. |

| |

| SYSTEM DESCRIPTION: |

| |

| The elements f system are: |

| • LVDT probe/pick up |

| • Signal conditioning electronics. |

| • Filter Electronics. |

| • ADC Electronics. |

| • Gear Mas™ III for Roll Tester. |

| • Linear Glass Scale. |

| • Counter Card. |

| |

| By rolling measuring gear with a master(free from backslash), the center distance will vary according to the errors of gear. This variation is is measured by an axial LVDT probe and signal conditioning electronics. The analog output is digitized by ADC electronics. The raw data is filtered (for separation of low and high frequency components of data) and use for evaluation of various parameters as mentioned below. Linear glass scale is fitted for accurate setting of center distance. |

| |

| FEATURES: |

| |

| • Evaluation of following parameters as per DIN3963: |

| • |

fi” - Double Flank Tooth error. |

| • |

Fi” – Double Flank Rotational deviation. |

| • |

Fr- Runout error/ Eccentricity error. |

| • |

Qualitative analysis of involute curve and pressure angle error graph. |

|

| • Entire DIN table pre-installed. |

| • Facility for user configurable Tolerance. |

| • Automatic detection of DIN grade measured jib data. |

| • Provision of archive/recall of standard and history data. |

| • Standard data can be taken from Gear Mas™ I Software. |

| • Built-in hardware diagnostics and software calibration facility. |

| • Generation of multi-colour scaled reports in graphical format. |

| • User friendly and menu driven operation. |

| • Open ended design provides easy scope for adding many more user desired features. |

| • Viewing measured graph at different magnification. |

| |

|

| |